Did you recently purchase the Czextruder in Colored Version?

Then see the Silver new crank handle?

Want both handles without buying another Czextruder?

There is a conversion kit.

Here is how to convert the handle

and where to purchase for pre-order.

There are two kits an XL and an XXL kit please purchase the one you have. If you are not sure please ask me if you purchased from me or send me a photo and I will tell you the one you need. the XL is 10cm and the XXL is 18cm long if that helps.

Above photo is the extruder opened.

Top Left photo is what comes in your XL extruder and XXL Czextruder box.

Bottom Left is what comes in the conversion Kit.

(a wrench, an extra plunger, a threaded shaft, a Jam Nut, A new crank handle, a hex bit for your t-handle and the use of a drill)

Right side is the example of the Czextruder in color.

Above is a photo of an XL Czextruder T-handle Colored Version

Above is a photo of the XL Czextruder Crank Handle New Version

All available in USA

through my Artfire shop

for purchase or pre-order

that arrives Mid. October 2013

Click the My Artfire to go to my shop.

Lets Begin.

Conversion of Czextruder handles

Click any instruction photos to enlarge them.

Photo above of what you should have in your Czextruder kit now.

Photo of conversion kit and accessories

Version 1 of how to convert handles.

There are two possible ways.

Tools and Directions

You will need a socket wrench, 13mm hex socket and a 5/16 wrench.

Take the full threaded piece out of your extruder.

Attach the hex socket and wrench to the large nut on the bottom end that goes towards the inside of the extruder when you extrude.

With your free hand attach a 5/16 wrench to the other smaller end of the threaded part of the extruder.

Hold tight with your hand and the 5/16 wrench.

Two gentle turns and one of two things happens.

Your hex bit inside the hex socket comes loose OR the end where the 5/16 breaks off clean.

Either is OK !!!

NO WORRIES EITHER WAY WORKS.

Three out of 4 times the small end snapped off clean.

With sand paper sand off any sharp edges. I found none.

Discard the piece that comes off you will no longer need it.

If you get lucky and just the Hex bit unscrews from the left side of the photo. Unscrew it and then unscrew the cap and set the threaded shaft aside for a spare in the future.

To assemble this way. Take the threaded shaft from your new handle kit. Be sure to screw on the cap first then the hex bit that you removed from the other and you are in business.

follow the rest of instructions below.

Don't want to do the above way?

That's ok. How about a saw?

Please wear protective eye ware

Recommend protective gloves

This type of saw will work or

This type of saw will work. Any brand is fine.

Please use safety. Cut away from yourself.

Watch fingers and any items that could be damaged.

I would recommend putting your threaded rod in a vise or have someone strong hold it for you.

Please be safe.

Using the saws above cut across the line that is in white in the photo on the bottom threaded piece. You will only cut off directly at the base of the threaded part. Do not cut off any thread as you need it.

Once the end is cut off discard the cut piece.

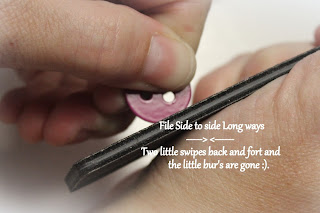

Sand off with sand paper any burs.

See more directions below.

Assembly

Assembly for first T-handle use.

In the kit is the Jam Nut. and a longer hex bit, hollow on one end hex on the other. You need these pieces for this step.

First tread on you Jam Nut. DO NOT TIGHTEN YET.

Then thread on the larger hex bit. Open end has threads. Thread it on. Do not thread it on all the way at first. Have to do a few experiments first.

1. once you have these pieces on put it back on your extruder colored shaft.

2. put the white plunger in the other end.

3. Put the t-handle on the hex bit end.

4. extrude Air. you need to extrude until the white plunger pops out completely.

did it pop out?

If not then move the hex bit back a bit and the jam nut back a bit.

You will have to play with this. Once you have it aligned so that your white plunger pops out your in business and your new handles are in perfect position.

At this time only tighten the Jam Nut where it is.

I recommend using a 5/16 wrench or the supplied wrench in the kit will do.

DO NOT OVER TIGHTEN.... Just a little bit more than hand tight is sufficient..

You do not want to strip any parts. Nothing on this tool needs to be more than hand tight. The caps, noting. They work best hand tight. So don't have your hubby do it or a neighbor. What you can untighten is sufficient.

Adding the t-handle.

The handle is magnetic as you know so it will attach well to the new hex you attached. Your ready to extrude clay..

Conversion to New Crank Handle

Remove the Hex bit by unscrewing it. Do not move the Jam Nut!

The inside of the crank handle is threaded.

Thread on the crank handle. If it does not meet up exact with the Jam Nut that is ok. As you want the Jam nut to be in place to make sure that your white plunger comes out.

***NOTE DO NOT USE ANY TOOLS TO GET THE WHITE PLUNGER OUT. YOU JUST NEED TO EXTRUDE IT ALL THE WAY OUT. YOU CAN PUT THE HANDLE IN EITHER END OF THE COLORED CzeXtruder SHAFT AND POP THE WHITE PLUNGER OUT EITHER END. **** you will damage your plunger if you use tools.

This is what your new handle conversion will look like except yours is colored.

If you have any questions or concerns email me or post a question here on the blog. Email is kimisdesigns@yahoo.com.

These instructions have been approved by the manufacturer as the best way to convert the handles. In the future if anything changes we will notify you.

Thank you and have fun extruding.

Tips from the CzeXtruder company.

! Do not tighten the end caps all the way czextruder without disk or clay, as it can cause damage the threads or the inner cylinder with o-rings!

! After each use, clean the inner cylinder czextruder from clay’s residue!

! From time to time, remove the o-rings from the cylinder and remove the clay and clean the grooves!

! Keep the cylinder with o-rings outside of barrels after the work and thoroughly cleaned of residual!

Click photos above to purchase items in the USA

Thank you for your support and I am always here to help. Customer service is my #1 priority and if you still need help I will do what I can.

Thank you for stopping by. Feel free to comment as I appreciate hearing from all of you.

If you have any questions email me @ kimisdesigns@yahoo.com

Hugs and Happy Creating to all ~

Create with Heart, Love, Color and Bling

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)